- Home

-

ENGINE / GEAR BOX

- Ferrari Major Service Kits

- Ferrari 328/Mondial 3.2 Major Service Kit

- 1975-1979 Ferrari 308 GTB/GTS/GT4 Major Service Kit

- 1980 Ferrari 308 GTSI/GTBI Major Service Kit

- 1981-1982 Ferrari 308 GTBI/GTBS/Mondial Major Service Kit

- 1983-1985 Ferrari 308 QV/Mondial Major Service Kit

- NFF 3.5 & 4 Liter Ferrari Engines

- Pistons & Connecting Rods

- Adjustable Timing Belt Systems

- Custom Camshafts

- Valves / Valve Guides / Seals

- NFF Custom Ferrari Head Gaskets

- Cylinder Head Porting

- Engine Management & Direct Coil Ignition Systems

- NFF Performance Radiators

- Ferrari Aluminum Radiators

- NFF Performance Water Pumps

- Supercharger Kits 308/328/Mondial

- 308/328/Mondial Harmonic Balancers

- Intake Manifolds

- Performance Clutches

- Gear Box Rebuilds / Differential Modifications

- Evans Coolant

- Engineering Services

- SUSPENSION

- INTAKE/ EXHAUST

- INTERIOR

- Used Parts

- AT26 Design Carbon Fiber

- Capristo Carbon Fiber

- Carbonio Carbon Fiber

- Leonardo Diagnostic tool

- Ferrari's For Sale

- Resto Hyper Mod Ferrari's

- About US

- Contact US

Nicks Forza Ferrari. The World's Oldest Capristo dealer

All Capristro exhausts are made of T309 grade stainless steel which has a higher temperature resistance than the commonly used 304 found in most exhaust systems today. T309 is comparable to inconel, which is a material used in Formula One exhaust systems. They are built on state-of-the-art production machines in Germany in order to accurately attain perfect fitment. All systems are are precision made to be installed on the worlds most expensive luxury cars.

All Capristo products carry a 3-year warranty. Capristo offers the entire range of aftermarket exhaust systems for various models for Ferrari, Maserati, Lamborghini, Porsche, Pagani, Audi, Mercedes, Bentley, Aston Martin, Corvette, Jaguar and Alfa Romeo. Make the most of your performance vehicle with an authentic Capristo exhaust system today.

All Capristo products carry a 3-year warranty. Capristo offers the entire range of aftermarket exhaust systems for various models for Ferrari, Maserati, Lamborghini, Porsche, Pagani, Audi, Mercedes, Bentley, Aston Martin, Corvette, Jaguar and Alfa Romeo. Make the most of your performance vehicle with an authentic Capristo exhaust system today.

Capristo Exhausts are renowned worldwide for their quality, design and enhanced sound. An increase in horsepower and sound through a more efficient design is experienced with these systems.

NEW PRODUCT ALERT

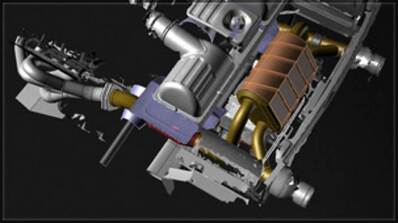

Ferrari 512/Testarossa – Headers/Exhaust Manifolds with Pre-Cat Connector Pipes (USA Spec)

**For USA Cars with Cats. These headers come with the connecting pipes (02FE05903013) that replace the OEM Cats. The connecting pipes connect the manifold to the OEM Secondary Cats.**

These High Performance Headers made from from T309 (1.4828) grade stainless steel were specifically designed for the Ferrari 512 and Testarossa.

The Capristo Manifold design eliminates both the primary and secondary catalytic converters for maximum flow.

The optimized flow design of these headers maximizes torque and horsepower in the midrange of the power envelope, right where the driver needs it. These headers are built as light and durable as possible.

The headers can also be used as a cost-effective substitute for defective OEM headers and cats.

Contact Us Directly For Pricing

Wayne 1.360.220.9388 or Nick 1.360.410.1949

These High Performance Headers made from from T309 (1.4828) grade stainless steel were specifically designed for the Ferrari 512 and Testarossa.

The Capristo Manifold design eliminates both the primary and secondary catalytic converters for maximum flow.

The optimized flow design of these headers maximizes torque and horsepower in the midrange of the power envelope, right where the driver needs it. These headers are built as light and durable as possible.

The headers can also be used as a cost-effective substitute for defective OEM headers and cats.

Contact Us Directly For Pricing

Wayne 1.360.220.9388 or Nick 1.360.410.1949

Capristo's design, production & testing.

|

1. LASER SUPPORTED MEASUREMENT - Capristo utilizes a 3D laser scanner which creates a 3D picture of the vehicle without ever touching it. This serves as a starting basis for the development of the prototype on the computer. 2. DATA PREPARATION - Capristo's scanned data is prepared, cleaned and exported in such a way that these can be further processed using their CAD-Software to give the parameters for the new Capristo exhaust. 3. CAD CONSTRUCTION OF SYSTEM - A virtual system is constructed which serves as the basis for the data to be constructed for Capristo's in-house production in order to begin with the manufacture of the prototype after market exhaust system. 4. COORDINATION AND ENHANCEMENT - One or more of the luxury exhaust system prototypes are tested and enhanced until after a perfect result is achieved. 5. COMPLETION - The finished construction of the Capristo exhaust system is now ready for serial-production and will now be produced based on the existing and precise guidelines. CNC-bending and milling, as well as other modern technology, guarantee the continuous quality at the highest standards for every aftermarket exhaust system produced. |

Nicks Forza Ferrari & Capristo Exhaust Systems.

Nicks Forza Ferrari have been modifying Ferrari's along with manufacturing and selling performance parts since 1996.

We are the longest continuous re-seller of Capristo products in the world and expect to be around selling these aftermarket exhaust systems for a long time.

We are proud to say that out of all the other brands of exhaust systems that we sell the Capristo brand stands out as the premier system for Ferrari, Maserati, Lamborghini, Porsche, Pagani, Audi, Mercedes, Bentley, Aston Martin, Corvette, Jaguar and Alfa Romeo. We've tested the other exhaust systems and always come back to Capristo.

We will meet or beat any other authorized distributors prices, our service is second to none and we know the product, quality and passion that Antonio Capristo puts into every system that is built for our clients worldwide.

I personally offer a promise of a quality product and the knowledge of the Capristo brand, along with commitment and passion for your super car. - Nick

Notice of Non-Affiliation & Disclaimer - Nicks Forza Ferrari is not affiliated, associated, authorized, endorsed by or in any way officially connected with Ferrari S.p.A. or any of its subsidiaries.

Location

- Home

-

ENGINE / GEAR BOX

- Ferrari Major Service Kits

- Ferrari 328/Mondial 3.2 Major Service Kit

- 1975-1979 Ferrari 308 GTB/GTS/GT4 Major Service Kit

- 1980 Ferrari 308 GTSI/GTBI Major Service Kit

- 1981-1982 Ferrari 308 GTBI/GTBS/Mondial Major Service Kit

- 1983-1985 Ferrari 308 QV/Mondial Major Service Kit

- NFF 3.5 & 4 Liter Ferrari Engines

- Pistons & Connecting Rods

- Adjustable Timing Belt Systems

- Custom Camshafts

- Valves / Valve Guides / Seals

- NFF Custom Ferrari Head Gaskets

- Cylinder Head Porting

- Engine Management & Direct Coil Ignition Systems

- NFF Performance Radiators

- Ferrari Aluminum Radiators

- NFF Performance Water Pumps

- Supercharger Kits 308/328/Mondial

- 308/328/Mondial Harmonic Balancers

- Intake Manifolds

- Performance Clutches

- Gear Box Rebuilds / Differential Modifications

- Evans Coolant

- Engineering Services

- SUSPENSION

- INTAKE/ EXHAUST

- INTERIOR

- Used Parts

- AT26 Design Carbon Fiber

- Capristo Carbon Fiber

- Carbonio Carbon Fiber

- Leonardo Diagnostic tool

- Ferrari's For Sale

- Resto Hyper Mod Ferrari's

- About US

- Contact US